A lot of you aerospace suppliers have been exposed to the spec “ASQR-01,” and a lot more of you are gonna be. For those of you who don’t know what it is, let me offer a brief and probably totally inaccurate summary. If you know this stuff already, skip the first part.

It’s Pronounced “ASS-kisser”

ASQR stands for “Aerospace Supplier Quality Requirements,” and ASQR-01 is a set of purchase order requirements that a set of major aerospace primes flow down on the POs to suppliers. (That was probably evident in the name.) That was the easy part, and literally nothing else I will tell you is easy.

So, who the hell came up with this? I have no clue because it popped up sometime in the 2000s, and I spent most of that decade in a drunken stupor when the world lost its damn mind and decided that Nickelback should be a thing. I believe the first versions were published by United Technologies Corp (UTC), which has its own labyrinthine history (you can read that here) but an alternate theory suggests it was actually created by Collins Aerospace, which was formerly known as Rockwell Collins. Since the organization “Collins” was formed in 2018 when Rockwell Collins was bought by UTC, and since ASQR-01 existed prior to 2018, it must have started as a UTC spec.

Since then, it’s gotten messier. In 2020, UTC merged with Raytheon to form yet another new org, called Raytheon Technologies Corporation. That company then included Pratt & Whitney, Collins and Raytheon. Then, Raytheon rebranded as “RTX” in 2023 because fuck you for trying to pay attention.

All that time, ASQR-01 kept being republished (it’s up to revision 14 as I type this), and updated with whatever corporate name sat atop the letterhead at that particular point in history. And, so, ASQR-01 began getting polluted with all sorts of legacy branding to mix with current branding, interblending the corporate names to such a degree that it not only makes writing articles like this difficult, it creates real-world problems with the ASQR-01 spec itself.

With the mergers and acquisitions, ASQR-01 has had to serve multiple masters. Whereas it was once just a UTC spec trying to pull together purchase order requirements for just UTC, once Collins got involved, ASQR-01 had to include those, too. But the Collins stuff wasn’t the same as the UTC stuff, so chaos started crowning like Rosemary’s baby. Then it started to karaoke “Mambo No. 5” and split into separate requirements for Pratt Whitney, Pratt Whitney Canada, UTC, and a little bit of RTX (is all I need) — all in the same document. That was true right up until Rev 13.

Because someone at RTX apparently liked that scene in The Dark Knight where Joker tells Two-Face, “I’m an agent of chaos,” with Rev 14, they plugged in another set of requirements, too: AS 13100.

So while The Joker said, “you know the thing about chaos? It’s fair…,” this chaos is anything but. It’s an absolute shit-show.

Everyone Loses Their Minds!

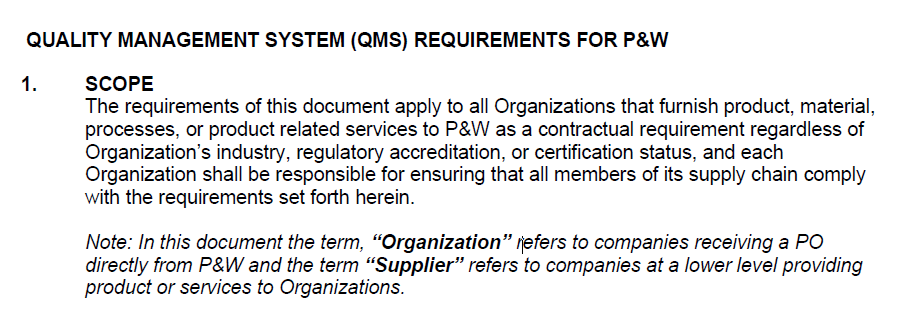

So let’s look at the madness that aerospace companies have to deal with now. First, ASQR-01 required that the signatory companies — specifically Collins, Pratt and Pratt Canada — flow it down to the “entire supply chain.” Do they define the term “supply chain?” Of course not; they define “supplier” and “organization,” but not “supply chain.”

Why does that matter? Because taken literally, if you get ASQR-01 flowed down to you, you have to flow it down to everyone you work with. And, since everything comes out of the dirt eventually, this means it would have to be flowed down to foundries, to smelters, and — yeah — the mines.

Obviously, that’s not what these clowns had in mind, but it’s what it literally says. So until they fix that, no one really knows how far down the “supply chain” to flow it. Which means, basically, everyone is in noncompliance with ASQR-01, even the idiots at Pratt & Whitney. (You know they’re buying stuff from McMaster-Carr, and that McMaster-Carr is definitely ignoring ASQR-01.)

Next, Collins required a separate annual self-audit when they flowed down their ASQR-01… but (depending on your reading of things), Pratt and Pratt Canada didn’t. Or did they? Because they published an audit checklist called ASQR-01 Form 1 that appeared to apply to everyone, with only about half the questions related to Collins, specifically. So this was never clear.

Next, the drooling crotchjockeys never figured out how to issue Form 1 at the same time as ASQR-01 itself, so Form 1 was always one revision behind the most current version of ASQR-01. Which used to be annoying, sure, but as of Rev 14 of ASQR-01, it’s now impossible to comply with. This is because of our next problem…

Some Men Just Want to Watch the World Burn

Some Men Just Want to Watch the World Burn

Previously, ASQR-01 followed AS9100… sort of. They ignored entire clauses they didn’t care about, so it was never a full one-to-one linkage.

With Rev 14, ASQR-01 still follows AS9100, but references requirements from AS13100, the SAE quality management system standard for “Engines and Systems” manufacturers. So what’s that, exactly? AS13100 is, itself, the product of some other Batman villain — let’s blame Clayface — who thought it would be cool to create an entirely separate aerospace QMS standard to compete with AS9100. (This is because AS9100 is largely written by Boeing, and the RTX gang hates Boeing, so they felt they should just create their own competing standard.) So now ASQR-01 requires conformity to that, which will be nightmarish news for all those small machine shops who already spent a fortune getting AS9100, only to find out that RTX doesn’t like it anymore.

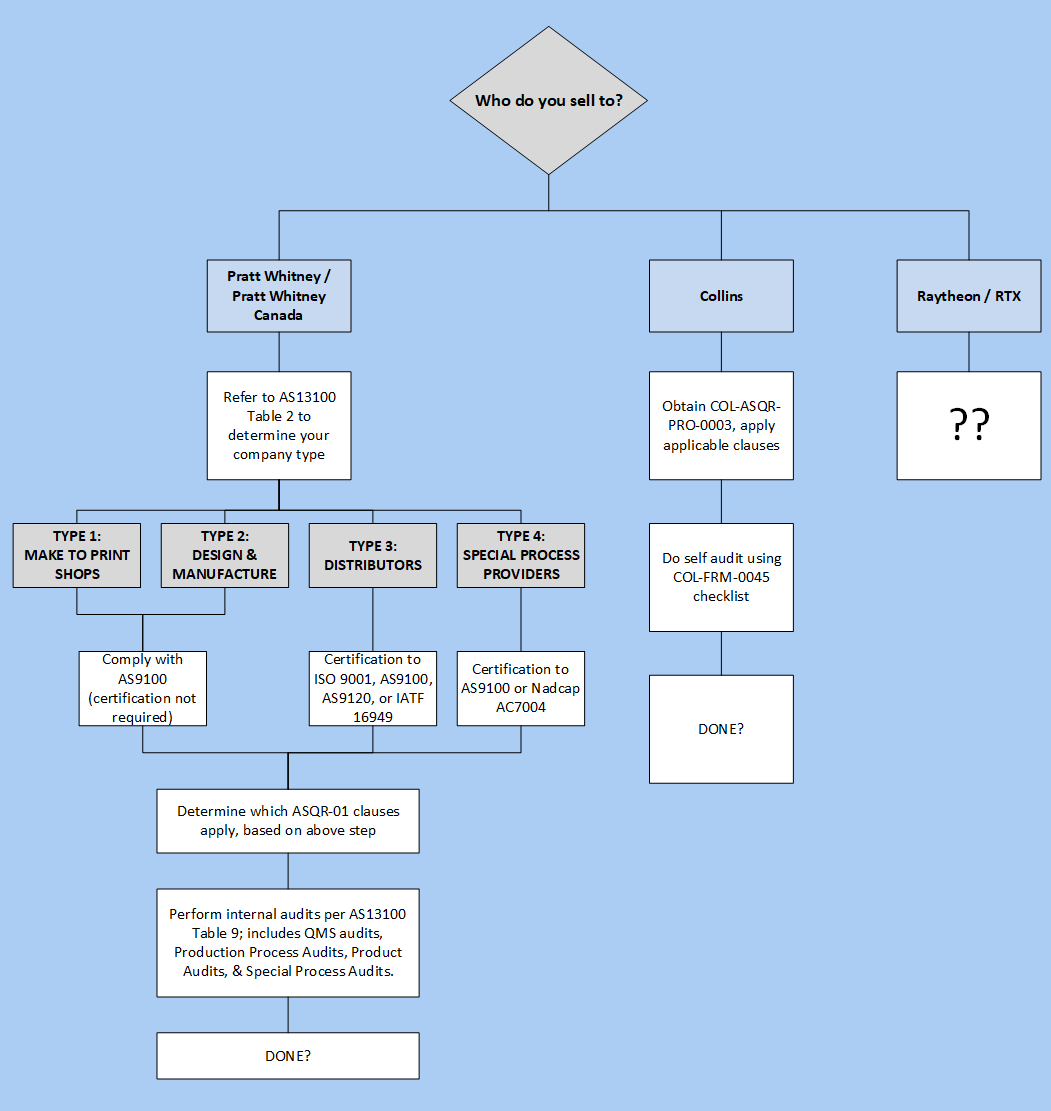

Oh, there’s more. For Rev 13, ASQR-01 was awkwardly balancing the requirements of Collins, Pratt, and Pratt Canada. But with Rev 14, they tossed the Collins requirements out completely, and a weirdo note in the beginning now tells readers that if they serve Collins, they have to comply with a Collins spec called “COL-ASQR-PRO-0003.” What ASQR-01 doesn’t say is whether Collins suppliers only have to comply with that, or the Collins spec plus ASQR-01.

If you’re not confused enough, the ASQR-01 requirements — which, again, appear to only apply to “P&W” suppliers — then reference RTX documents, like the “RTX QDL” (Qualified Distributor List.) So, yeah… another party heard from.

The most generous reading to ASQR-01 is that, no, if you serve Collins, you only have to comply with COL-ASQR-PRO-0003 and that ASQR-01 now only applies to POs coming from Pratt & Whitney and Pratt & Whitney Canada. (A fun annoyance: the table at the beginning defines the companies as “PW” and “PWC,” but then the text immediately abandons these abbreviations and simply refers to “P&W”. God fucking forbid a company like Pratt should hire a goddamned editor.) This seems to be supported by the latest rev of COL-ASQR-PRO-0003, which removed callbacks to ASQR-01, making it a standalone document.

Except, Collins is still requiring ASQR-01 self-audits in their PO terms and conditions (for some suppliers, anyway.) So how do you do a self-audit to ASQR-01 Rev 14, if the audit form is only at Rev 13 and doesn’t line up at all with the actual requirements of the spec? If you serve Collins, you should perform a self-audit using Collins form “COL-FRM-0045” and against COL-ASQR-PRO-0003. Your PO may not call out that, though, so if they are demanding an ASQR-01 Form 1 audit, you’ll have to talk to your Collins rep. (Good luck with that!)

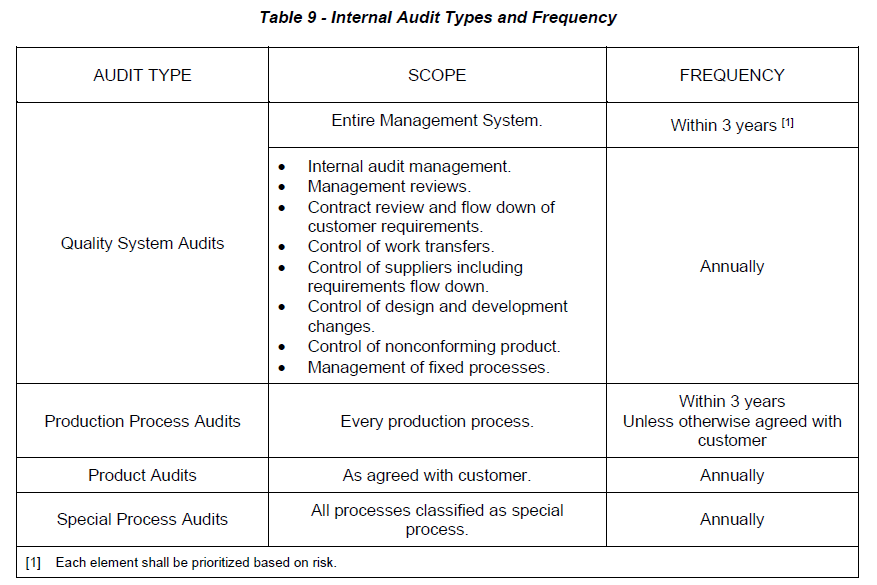

If you don’t sell to Collins, then you just have to follow the new ASQR-01 Rev 14 requirements for a self-audit, and you’re not gonna like it. ASQR-01 points you to “Table 9” of AS13100 and its internal audit requirements are experiencing some “aggressive expansion,” to say the least:

The good news is that AS13100 gives QMS audits a break — you only have to audit the system every 3 years, with the exception of the management-y stuff. That bad news — which is very bad — is that it adds a host of additional audits you have to conduct: Production Process Audits, Product Audits, and Special Process audits. (Presumably you can skip the Special Process audits if you don’t have a special process… presumably. Another interpretation is that if you outsource your special process audits, then you still must audit each special process provider. Fun!)

But all that auditing for most machine shops is going to put them out of business.

Are you listening, Pratt? No one is going to comply with your batshit insane requirements, because not everyone has Pratt & Whitney money! And you’re an asshole for asking!

AS9100 or AS13100?

ASQR-01 also utterly confuses what standard actually applies here. Rev 14 is numbered to follow AS9100, but then discusses AS13100 requirements, and has almost nothing to say about AS9100 itself. Really?

Up front, it says, “supplier receiving a purchase order from P&W shall comply with the requirements of AS13100 and ASQR-01.” That’s unambiguous: if you get a Pratt PO, you gotta do everything in AS13100 and ASQR-01. The very next sentence then says, “The following P&W company-specific requirements are aligned to the numbering scheme of AS9100 and AS13100.” The problem here is that while most of AS13100 follows the numbering scheme of AS9100, AS13100 then adds a ton more content, effectively adding clauses 11 through 21 (whereas AS9100 stops at clause 10.) So which standard are we talking about?

Next, ASQR-01 says that if you’re a manufacturer, you only need to comply with AS9100, and not be certified to it. That’s a relief, but it’s also insane. Especially since they then say that if you’re a distributor you need to get certified to AS9120 or… wait for it … AS9100, which is for manufacturers, not distributors! So the Pratt dummies don’t even know the scope of the standards they are demanding of people.

Seriously, Pratt: why are you requiring certification for distributors and not manufacturers? Distributors are a lower risk, you window-licking mudpie eaters. Your real supply chain problems are the first-tier manufacturers. I suppose The Riddler cooked up that one.

But it’s all moot anyway, since the ASQR-01 spec itself calls out major elements of AS13100, like PPAP, MSA, FMEA, etc., so anyone compliant or certified to AS9100 will be absolutely batshit baffled anyway. AS13100 is a monstrous addition to AS9100, adding a full 40 more pages.

And even worse yet, so many of the AS13100 callouts would be way the hell out of scope — and capability — for traditional make-to-print shops. Why would a dowel maker need to do PPAPs? Is Pratt ready to pay the extra money those suppliers are gonna charge them? (Hint: no, they are not.)

Now remember that Pratt (or Raytheon or RTX or whoever the hell it is) requires that ASQR-01 be flowed down to “all” members of the supply chain. Here’s the screenshot:

So, Machine Shop A has to flow it down to Aluminum Sheet Provider B, who then has to flow it down to Aluminum Foundry C, who then has to flow it down to, I dunno, … Alcoa I guess, who would then have to flow down ASQR-01 to the bauxite mining company Surinaamsche Bauxiet Maatschappij in Suriname.

Good luck with that, Pratt!

Wanna See How I Got These Scars?

I worked up this flowchart to summarize this mess, but I can nearly guarantee (a) it’s wrong, and (b) I will be updating this every five minutes for the next few weeks as people smarter than me point out all the errors. But you get the idea.

Again, this level of pedantic, bureaucratic ass-covering is just so Pratt and Collins can play legal CYA when their shit falls out of the sky. But this creates fraud. This induces contract violations. If you make your POs so legally tangling that no one can comply with them unless they go out of business, you will have two inevitable end results: you won’t have a supply chain anymore, or everyone will just lie to you.

Hey, Pratt and Collins, c’mere. Pull in close, I have to tell you something, and you’re not going to like it. What you are requiring is moonshot level stuff, but you’re asking it of model rocket enthusiasts. Your supply chain can’t comply with your insanely complex requirements, nor do you really want them to. If the “entire supply chain” obeys your batshit insane requirements, the cost of every nut and bolt will be so high, you will be out of business in a week. Because you are literally driving away key lower-tier suppliers who have low risk, but who sell to your tier 1 suppliers. Those small machine shops are not your problem, you morons. It’s the big guys you’re buying from, you know, the ones you don’t dare hold accountable because then you’d have no suppliers.

So just stop already. Do the hard work and figure out exactly which suppliers in your supply chain need these requirements, and apply it to them on case-by-case. Stop making up impossible requirements and thinking you have enough stick in the industry to flow it down to everyone. You don’t. You’re not that important. You’re just fucking lazy.

[Image credit: Joker painting by Mariart89; visit her DeviantArt page here.]

Christopher Paris is the founder and VP Operations of Oxebridge. He has over 35 years’ experience implementing ISO 9001 and AS9100 systems, and helps establish certification and accreditation bodies with the ISO 17000 series. He is a vocal advocate for the development and use of standards from the point of view of actual users. He is the writer and artist of THE AUDITOR comic strip, and is currently writing the DR. CUBA pulp novel series. Visit www.drcuba.world