(UPDATED 12/17/2014 – see below)

IRCA ISO 9010 Lead Assessor trainer, and self-published book author, David Seear has spent the better part of the last ten years (or more) pushing a concept he calls “Back to Basics.” The collective thesis is tough to suss out, since David writes this stuff in manifesto style and admits his command of English (despite being from the UK) is poor. But in short, he believes the root cause of ISO 9001’s problems relates to confusion over the purpose of ISO 9001, as well as ignorance of what he calls the “ISO 9000 Family of Standards.”

His most recent approach has been to post a series of “Back to Basics” questions on LinkedIn, under the guise of him seeking consensus. One is quick to discover that David Seear is not seeking consensus, he is seeking something quite different: complete agreement with his point of view. Failing that, David is very happy to accept the consolation prize of victimhood, repeatedly claiming how no one understands him, or how he is the victim of “bullying” and “character assassination.”

There’s too much material to go over in one article, and for the most part David’s material comes off as harmless, the stuff of a once-kindly old man who, because of recent medical issues, is now camped on his lawn yelling at the neighborhood kids and butterflies. But his recent puffery became a bit more serious when he revealed his notion of sampling during audits, all done under the IRCA banner.

The first thing I normally do is walk through the organisation to see what is taking place at that time. It gives you a chance to see the layout as well as make a note of job numbers that are currently being dealt with. Then from those jobs I would take a sample. Usually at least three but that depends on the time I have been allowed.

So David Seear thinks sampling should not only be based on only active orders, but an arbitrary sample size of “usually at least three.” And then he admits the whole thing gets filtered by how much time he has. No defined sampling plan, no statistical considerations, no assessment of whether those orders that happened to be running that day are even indicative of the company’s normal workload. Nada.

It gets worse. On another thread, David admits to being pressured by competition to reduce audit days.

This is the competative [sic] nature of certification. Having been a certifcation manager using the AMDAC table for man days I ended up getting little work as I priced at double the days required by others. In fact a competing certification organisation told organisation that they would undercut what ever I said by more than 10%. Made it difficult so I moved out.

David Seear claims this is a “process approach” to auditing. I disagree (here’s my take) and — as most of us know — this is the exact method of auditing that’s been done for decades prior to the ISO 9001:2000 edition which introduced the process approach. It’s a bad approach, it runs contrary to the rules, and while it’s nearly universal, no one has so openly admitted it before.

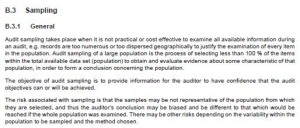

ISO 19011 provides guidance on how to audit management systems, including ISO 9001, and even has a full section (Appendix B.3) on sampling. That standard clearly defines the methods for determining sample size, based on two possible appraoches: a statistical approach, or a judgment-based approach. Neither approach limits objective evidence to the criteria David Seear makes his priority: a limited number of open orders, no closed orders at all, and then filtering all of that based on available time.”

Now normally David Seear uses his “ISO 9001 Family of Standards” to cram down other people’s throats. I call it “his” Family of Standards, because David does not recognize all the supporting standards as defined by ISO, but instead only ISO 9000, 9001 and 9004. In his book “ISO 9001 Audit Trail,” he begrudgingly acknowledges ISO 19011, but in his sampling method, he ignores it entirely.

When I questioned David on this, he invoked his IRCA credentials.

The one thing you are correct about is that I am an IRCA Principal auditor and trainer. The difference is I teach people to audit by taking a selective sample then find out for each of the samples what the requirements and specifications is. Then having taken the samples look in detail at what is called up from the contract/order from drawings or other specifications. Using this information and my own skills I then audit the processes by following an audit trail knowing what each process should achieve.

If that quote seems to disagree with IRCA, well… that’s the way I read it, too. So to see what’s going on, I wrote to IRCA. I gave them David’s explanation of sampling, and asked if that was supported by IRCA’s interpretation, and if it was an official IRCA method. I did not mention David’s name. Here is what IRCA Technical Manager Richard Green wrote back:

I can confirm that ‘picking a set number of active orders (around 3)’ is certainly not an approach to sampling IRCA would wish to see its tutors passing on to delegates attending our Lead Assessor courses.

Our Auditor/Lead Auditor course criteria are written at a high level and consequently they do not explicitly detail the instruction to be provided in respect of sampling. We would however expect our trainers to cover the determination of a ‘representative sample’ by reference to population size, sample size and sample composition as well as the most appropriate analysis method (judgement based vs statistical based sampling) depending on the sampling objectives that have been set.

If you are able to provide details as to the course where this behavior was witnessed we will endeavor to contact the training organisation responsible. It is important that the correct message is given out to delegates on future courses.

UPDATE 12/17/2013:

It’s not clear why IRCA would be surprised by this sampling method. In December 2009, IRCA published an article by David Seear in which he pretty much laid out the same plan:

For example, as a matter of course auditors will visit the shop floor. This enables the auditor to see what is taking place and to identify the specific order numbers of jobs that are going through at that time.

At any rate. when presented with IRCA’s position, David Seear just dug in:

In fact I have had as many disagreements with IRCA as I have with you. You indicate that what I do conflicts with my IRCA credentials well I have to advise you that they do not. I teach auditing as it should be carried out.

David then gave me permission to alert IRCA of his position and launch an investigation. I will let IRCA handle that part, but I don’t expect that they will be very pleased that one of their trainers not only disagrees with their interpretation, but he doesn’t care.

Considering he rates his own books “five stars” without any sense of self-awareness, this probably shouldn’t be a surprise.

Christopher Paris is the founder and VP Operations of Oxebridge. He has over 35 years’ experience implementing ISO 9001 and AS9100 systems, and helps establish certification and accreditation bodies with the ISO 17000 series. He is a vocal advocate for the development and use of standards from the point of view of actual users. He is the writer and artist of THE AUDITOR comic strip, and is currently writing the DR. CUBA pulp novel series. Visit www.drcuba.world