The Nadcap advisory demanding “dimensional inspection” of all anodize parts in lieu of thickness checks has been rescinded, in a dramatic slap to the Performance Review Institute (PRI) after widespread industry backlash.

In late 2019 a PRI auditor wrote a minor Nadcap audit finding related to an anodize provider’s inspection methods. That finding was then escalated to a major finding by Nigel Cook, PRI’s Lead Staff Engineer for Chemical Processing. Cook then expanded the issue, by declaring that testing the thickness of anodize coatings did not constitute a dimensional inspection, which he claimed was required by MIL-A-8625. Cook issued formal PRI Advisory CP 20-003 on the issue, and Boeing representative Andy Murphy simultaneously released an official Boeing Tip Sheet supporting the PRI Advisory. Both advisories demanded that in order to comply with MIL-A-8625, all anodize shops must perform full dimensional inspection if they have not obtained a written waiver from their customer, or face major nonconformities.

The move not only re-interpreted a standard that has been in place since the 1980s, but would have bankrupted anodize shops who typically measure coating thickness with low-cost, yet reliable, electronic probes. To comply with PRI’s ruling, such shops would be forced to invest millions of dollars in expensive coordinate measuring machine (CMM) inspection equipment and related inspector training. The average salary for CMM inspection operators is higher than that of standard anodize inspectors, meaning this would have increased payroll costs as well.

It was unlikely that Boeing or other aerospace primes would have agreed to any cost increases due to the changes, thus forcing the anodize process houses out of business.

PRI and Cook would not budge despite widespread outrage even from within aerospace primes and anodize industry professionals.

At least one major aerospace prime had drafted a directive advising their Nadcap accredited suppliers to ignore Cook’s ruling, but it was not released.

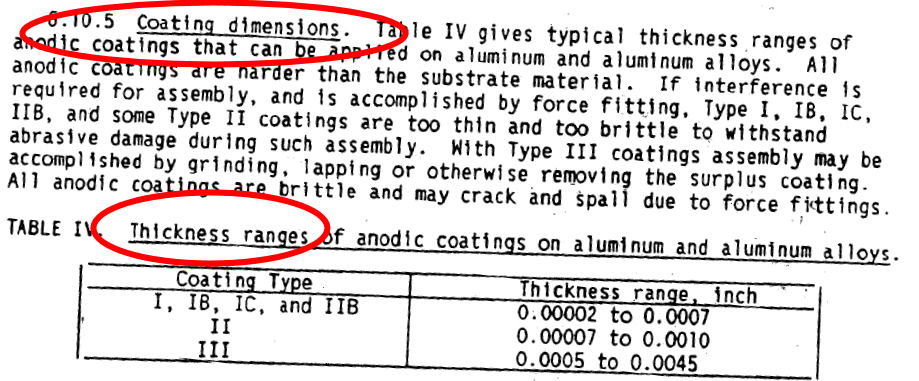

Oxebridge reached out to the Navair official representative of the committee responsible for MIL-A-8625, Rade Savija, who debunked PRI’s interpretation, and stated that the specification did not require dimensional inspection. In his ruling, Cook had quoted clause 6.10.5 of the spec, claiming the title “coating dimensions” indicated that dimensional inspection was thus required. Cook failed to notice that the clause is non-binding guidance information designed for part designers, not anodize providers, and that the supporting Table IV within that clause then defines “coating dimensions” in terms of “thickness ranges.”

Nevertheless, Cook ruled that “dimensional inspection is not thickness testing.” Oxebridge has argued that this counters simple Euclidean geometry, by arguing that thickness is not a dimension.

In an emergency stakeholder meeting called by Spirit on Tuesday, Nadcap voting members overwhelmingly rejected PRI’s ruling, voting 18:6 to rescind it. Despite the Advisory being rescinded, Cook has nevertheless continued to demand that PRI auditors issue major nonconformities until the MIL spec itself is updated. With the PRI advisory tossed out, the threat appears to be an empty one aimed at ensuring Cook and Murphy save face, and nothing more.

Nevertheless, PRI has so far refused to remove the Advisory from the public listing in its eAudit portal. If PRI were to issue any nonconformities against its now-defunct advisory, it could face legal challenges and industry class action suits.

Due to Cook’s intransigence, Navair has already drafted Amendment 2 of the spec and is preparing to publish it. The revised spec, Oxebridge has learned, will go far beyond merely clarifying the point, and instead remove all references to “dimensional inspection,” in what can only be seen as a huge slap to PRI, Cook and Murphy.

The amended draft — now titled MIL-PRF-8625F — can be downloaded here.

The MIL-A-8625 spec has existed for over 40 years, and PRI has been auditing companies against it for decades, and never raised this issue previously. When asked to defend his decision, Cook said he relied on “word search” to determine many times the word “dimension” appeared in the spec. Cook did not respond when pointed to the language of the spec which defined “coating dimensions” as being measured by “thickness.”

The result is a huge win for anodize providers worldwide, who have been reconsidering Nadcap accreditation given PRI’s inability to correct its error.

Oxebridge has called on Cook to resign for his role in the debacle, and for Murphy to step down from all PRI and Nadcap related responsibilities. The incident has become a dramatic example of how bad auditing and auditor interpretations can have world-spanning implications.

You are correct that the PRI ruling is nonsense. However, your arguments about ‘thickness as a dimension’ are a bit off the mark.

All surface treatment professionals know that you plate (including anodizing, which isn’t really plating) to a target thickness, NOT to overall part dimensions. We virtually made this a company policy, and never sold treatments to customers who were asking us to target an overall finished dimension. The methods to measure thickness and dimensions are obviously different, and really PRI are just using industry shorthand because they know that plating-to-thickness and plating-to-dimension are different.

The key Nadcap mistake was in interpreting the MIL spec as requiring that dimensional inspection was compulsory, when in fact it was nothing of the sort. To the best of my memory, no auditor has ever touched section 6.10 in a live audit.

I’m surprised that all this slipped through Nigel Cook. I have had dealings with him personally in the past, and he seemed genuinely knowledgeable and helpful towards special process houses. I’m guessing he must have backed himself into a corner and not had the guts to admit he was wrong. Shame.

It’s good that Navair got on board quickly and up-issued the spec. Kudos to them for not being at all ambivalent about it. The aerospace industry – with some justification – is very attached to ‘if it ain’t broke, don’t fix it’ specifications, so it’s good that someone had the wherewithal to get on the case quickly.